What Are the Key Applications and Trends for Forklift Batteries?

Forklift batteries are essential for powering electric forklifts used in warehousing, logistics, manufacturing, and cold storage operations. The key trend is the rapid shift from lead-acid to lithium-ion batteries due to faster charging, higher energy density, longer life, and lower maintenance. Other major trends include smart battery integration, innovative charging solutions, sustainability, and digital transformation in material handling.

What Are the Main Applications of Forklift Batteries?

Forklift batteries are primarily used in warehouses, logistics hubs, manufacturing plants, and e-commerce distribution centers. They provide the power needed for lifting, transporting, and stacking goods efficiently. Lithium-ion forklift batteries are especially beneficial in environments that require high uptime, reliable performance, and minimal downtime.

How Are Forklift Batteries Used in Warehousing and Logistics?

In warehousing and logistics, forklift batteries power electric forklifts that streamline material handling. Lithium-ion batteries allow continuous operation with opportunity charging during breaks, ensuring maximum productivity. The e-commerce boom has increased demand for battery-powered forklifts to handle high-volume, around-the-clock operations with reduced downtime.

Why Are Lithium-Ion Batteries Better for Cold Storage Applications?

Lithium-ion batteries perform better in cold storage because they retain more capacity and voltage stability in low temperatures compared to lead-acid batteries. This ensures reliable forklift operation in refrigerated warehouses. HeatedBattery offers lithium solutions optimized for cold-chain logistics, reducing power loss and ensuring safety in extreme cold conditions.

Which Industries Benefit the Most From Advanced Forklift Batteries?

Industries such as e-commerce, retail distribution, automotive manufacturing, and food logistics benefit most from advanced forklift batteries. These industries require fast, reliable, and efficient material handling. Lithium-ion batteries deliver longer runtimes, faster charging, and lower total cost of ownership, making them the preferred choice.

What Trends Are Driving the Shift to Lithium-Ion Forklift Batteries?

The main trend is the replacement of lead-acid batteries with lithium-ion due to:

- Faster charging with opportunity charging

- Longer lifespan with thousands of cycles

- High energy density for extended operation

- Low maintenance with no water topping or acid management

- Improved cold performance in refrigerated environments

How Are Smart and Connected Forklift Batteries Changing Operations?

Smart forklift batteries integrate with warehouse management systems (WMS) to provide real-time data on charge levels, performance, and predictive maintenance. This connectivity reduces downtime, extends battery lifespan, and helps managers optimize fleet scheduling and energy use.

Table: Traditional vs. Smart Forklift Batteries

| Feature | Traditional Battery | Smart Battery (Lithium) |

|---|---|---|

| Charging Insights | Manual checks | Real-time monitoring |

| Maintenance Alerts | None | Predictive notifications |

| WMS Integration | Not supported | Fully integrated |

| Downtime Impact | High | Significantly reduced |

What Role Do Fast-Charging Solutions Play in Forklift Operations?

Fast-charging and opportunity charging eliminate the need for battery swapping. Lithium-ion systems can recharge quickly during operator breaks, ensuring forklifts remain in service. This innovation improves warehouse productivity and reduces the total number of spare batteries required.

Why Is Sustainability a Growing Factor in Forklift Battery Adoption?

Sustainability is a major driver as companies move to reduce emissions and energy costs. Lithium-ion forklift batteries produce zero emissions, require less maintenance, and lower energy consumption compared to internal combustion forklifts. HeatedBattery designs eco-friendly solutions that align with green policies and corporate sustainability goals.

How Do Forklift Batteries Affect Total Cost of Ownership (TCO)?

Lithium-ion batteries reduce TCO through lower maintenance costs, faster charging, and fewer replacements. Although initial investment is higher, the long-term savings in energy, labor, and downtime make lithium-ion the more cost-effective choice for large fleets.

Chart: Cost Comparison Over 5 Years

- Lead-acid: High maintenance, frequent replacements

- Lithium-ion: Higher upfront cost, but lower lifecycle cost

When Should Businesses Upgrade From Lead-Acid to Lithium-Ion?

Businesses should upgrade when high uptime, fast charging, or cold storage performance is critical. Companies with large fleets or 24/7 operations benefit the most from switching to lithium-ion forklift batteries, as the technology eliminates many limitations of lead-acid.

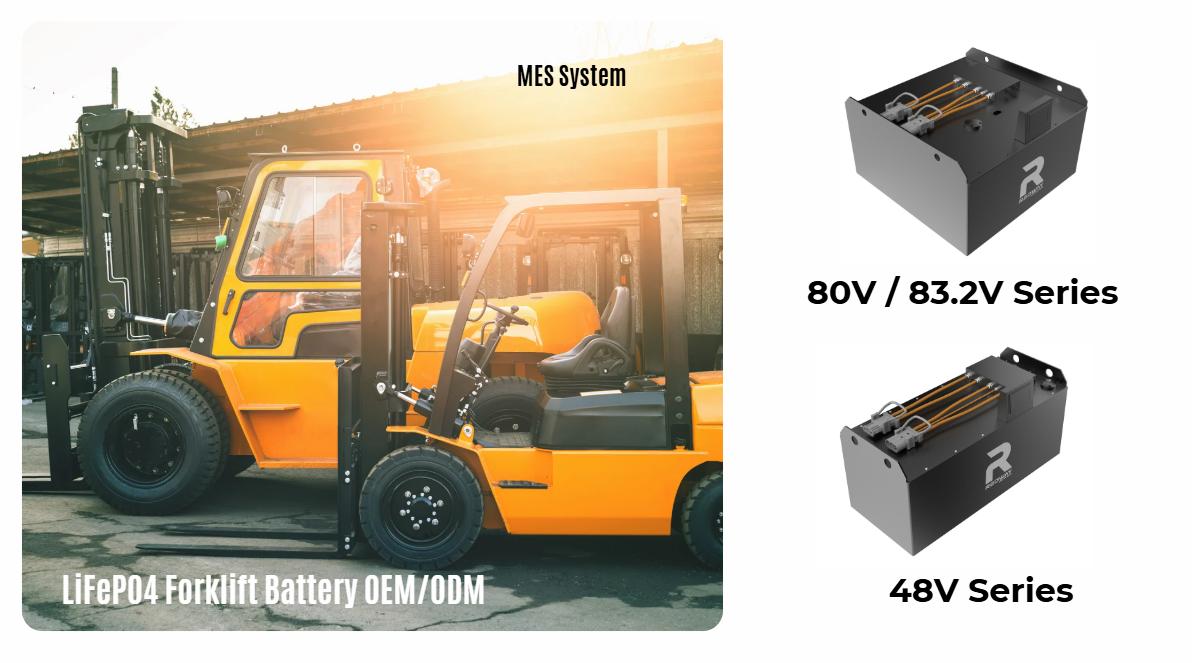

Can HeatedBattery Provide Customized Forklift Battery Solutions?

Yes, HeatedBattery delivers customized lithium-ion forklift battery solutions tailored to logistics, warehousing, manufacturing, and cold storage needs. With advanced BMS integration, long cycle life, and compliance with safety standards, HeatedBattery ensures reliable power solutions for global businesses.

HeatedBattery Expert Views

“Forklift battery technology is evolving rapidly, and lithium-ion has emerged as the new standard for performance, efficiency, and safety. At HeatedBattery, we focus on integrating advanced monitoring, fast-charging, and energy optimization into our forklift battery systems, helping industries reduce costs while moving towards a greener and more sustainable material-handling future.”

Conclusion

Forklift batteries are critical for logistics, warehousing, and manufacturing efficiency. The market is shifting from lead-acid to lithium-ion due to faster charging, durability, and sustainability. Trends like smart connectivity, fast-charging, and automation integration are reshaping material handling. HeatedBattery continues to lead with innovative, eco-friendly forklift battery solutions that improve performance while lowering long-term costs.

FAQs

Which forklifts use lithium-ion batteries?

Electric forklifts in warehousing, logistics, and manufacturing widely use lithium-ion batteries for efficiency and reduced downtime.

Do lithium forklift batteries need maintenance?

No, unlike lead-acid, lithium batteries require minimal maintenance, eliminating tasks like water topping.

Are lithium forklift batteries safe for cold storage?

Yes, lithium batteries perform better in low temperatures, maintaining stable voltage and capacity.

What is the lifespan of a lithium forklift battery?

Lithium-ion forklift batteries can last 3,000–5,000 cycles, far longer than lead-acid options.

Does HeatedBattery manufacture forklift batteries?

Yes, HeatedBattery provides advanced lithium forklift battery solutions with smart integration and safety features.